What We Can Make

We broaden our competency to make more possibilities.

Wide Variety of Connector Types

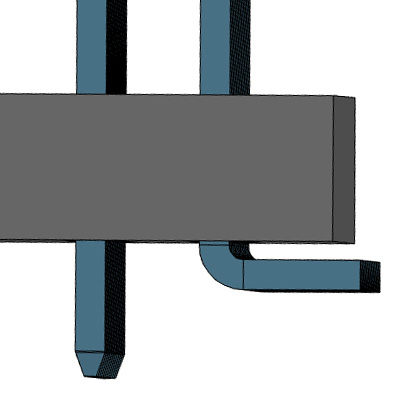

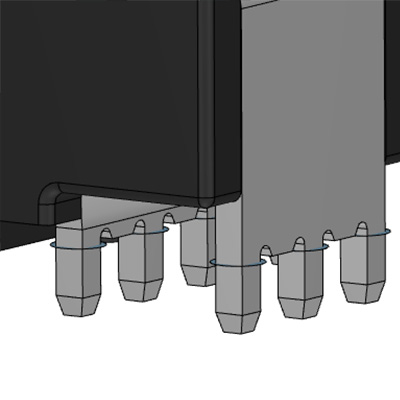

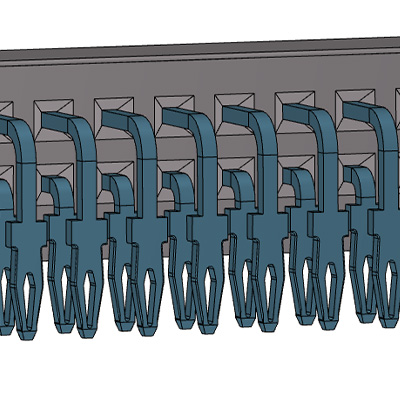

Contacts in connectors play a crucial role to transmit signal and power when connectors are mounted on board. To fit with different board-mounting process like THT(DIP), SMT, THR(Pin in Paste), or Press-in, the contact structure in our connectors can be of large diversity.

High Output of Assembly Production

To cater to high capacity demand for global market, we shorten the cycle time of our molding and assembling processes to accomplish high production output and upkeep stability and consistency in products at the same time.

Our shortest cycle time in connector assembling process can be down to 2 seconds per piece from material-feeding to part-packaging, and this makes us capable of churning out up to 8 million pieces of parts a year at most.

Customized Connectors

Standard Connectors

Cable Assemblies

Functional Plastics/Terminals

Terminals in types including Tab, SQ, Compliant Pins

How We Advance

We deepen our craftsmanship to reach higher precision

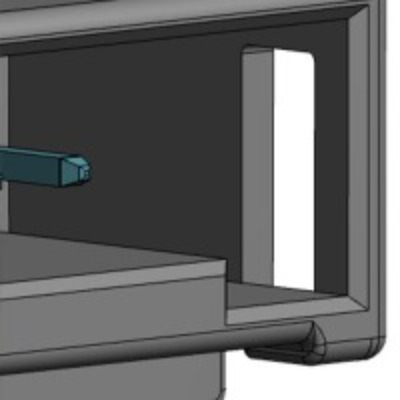

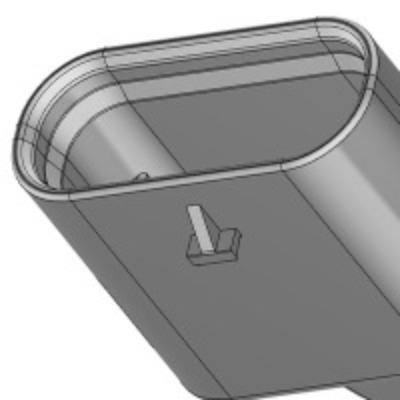

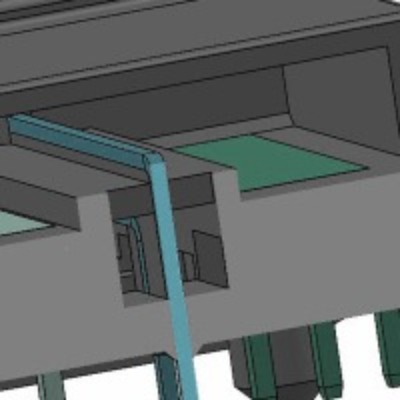

High Complicatedness of Plastic Molding

To become an expert in plastic manufacturing, we have gone through countless difficulties and challenges in designing and constructing our tools. Ultimately, we have acquired the capabilities to fabricate the most complicated shapes and structures in plastics.

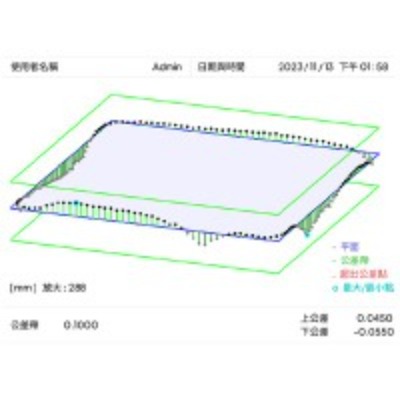

Going against plastic’ tendency to shrink and warp in molding process, we have taken significant stride in our molding technique to meet the most rigorous requirements for plastic profile, parallelism, and flatness.

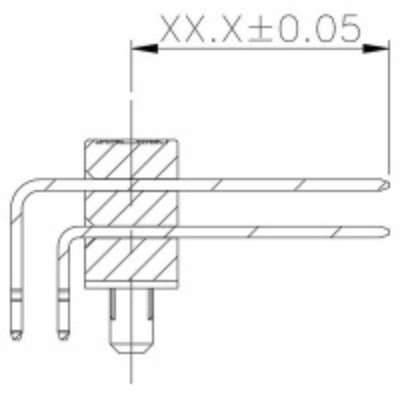

High Precision of Manufacturing Craftmanship

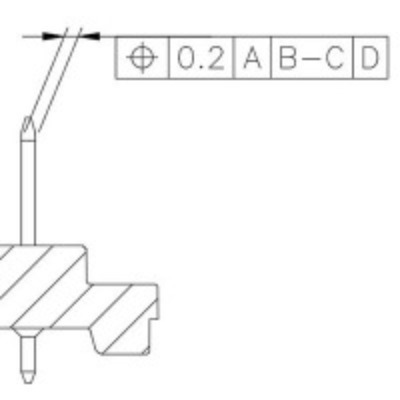

When terminals and housings are assembled to fabricate connectors, any deviation present in the terminals and housings contributes to add on to the overall deviation of the connectors. We highlight this aspect and continually strive to discover the optimal methods to achieve higher precision in connector manufacturing.

Our consistent efforts result in precise control over dimensional tolerances at their narrowest, attainment of the smallest true-position in pins, and assurance of the utmost coplanarity among terminals in connectors.

Our Equipment

2.5D measuring projector

FISCHERSCOPE X-RAY XULM 240

Mitsutoyo CMM instrument CRYSTA-Apex S 574